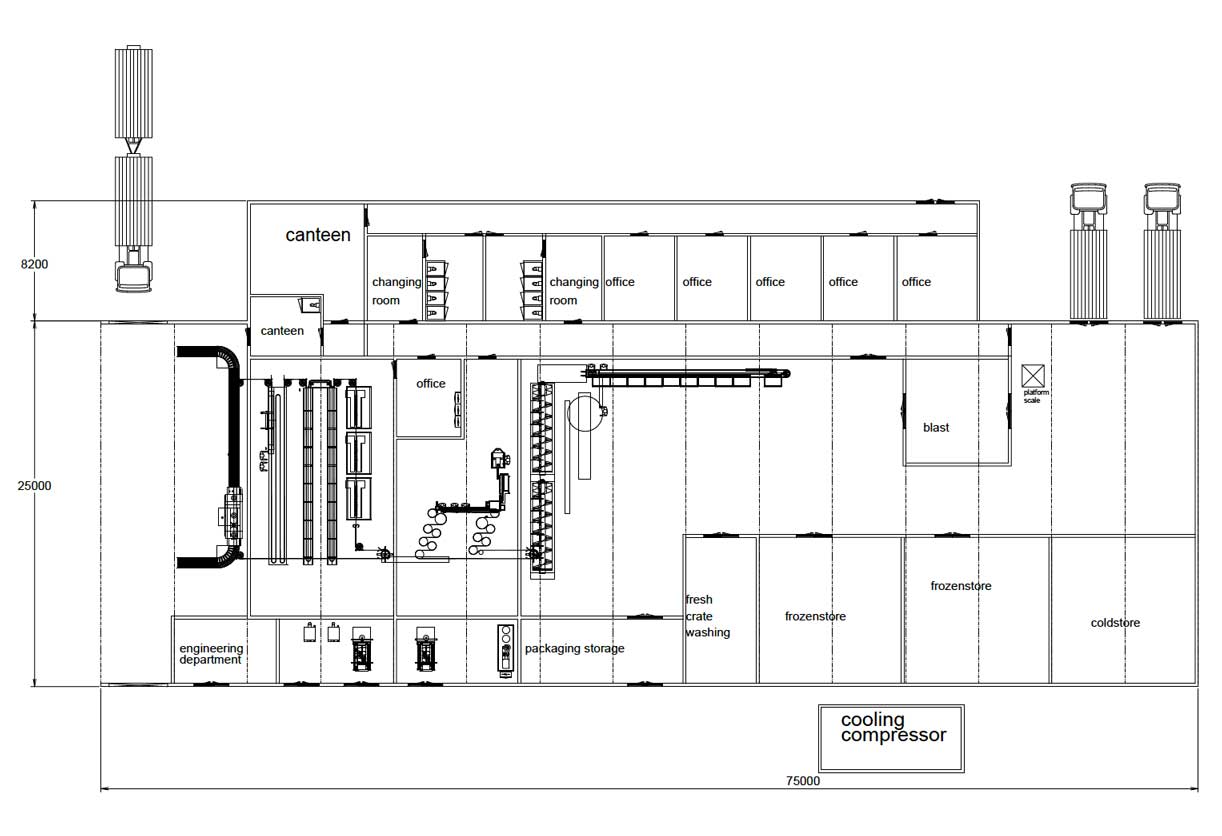

Virtual Tour

Only works on computers with a mouse,

Move your mouse over the image and click for more information about that part.

Arrival

Arrival

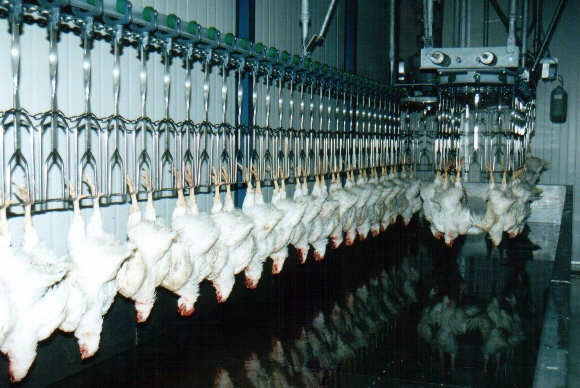

The arrival section, also live bird receiving or handling area, is the first step in the poultry processing production cycle. Live birds are brought to the poultry processing plants in crates, which are generally transported by lorries or trucks. The crates are unloaded, the birds are taken out of the crates and are hung in the shackles of the killing and plucking line. Generally the crates are placed on roller tracks or conveyors for easy and quick transport. The empty live bird crates are washed and sanitized before they are returned to the trucks.

In higher capacity plants the crate handling, stacking and destacking of crates and even crate washing is (semi)automated. Machines are able to take over many tasks in this area. In countries with low wages or in plants with lower capacities per hour, it can still be economically feasible to carry out many of these tasks manually using line personnel. Hanging the birds is still done by hand, even in the highest capacity plants.

When the birds are placed in the shackles of the killing and plucking line, they enter the next phase of poultry processing.

Stunning

Stunning

Due to religious concerns, poultry processing plants in these markets do not utilize a stunning device. In most countries, however, the birds are tranquilized before they are killed, rendering them unconscious and making them insensible to pain. This is done to improve animal welfare and in some countries it is even required by law.

Stunning by waterbat is a widely used method. It entails creating an electrical circuit by wetting the birds head. The electric stun will immobilize the birds and cause them to loose consciousness before they are killed. Immobilization has an added positive effect that it allows for clean, efficient and consistent killing cuts, meaning birds will not be harmed or hurt unnecessarily. Killing is then done by hand using a knife or by an automatic machine with one rotating blade.

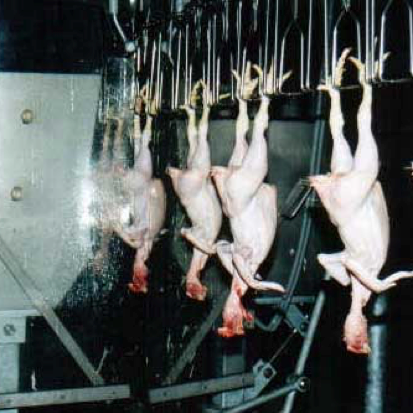

Killing & Bleeding Line

Killing and bleeding area

Following stunning, the blood vessels in the animal's neck are cut to kill the bird and to allow it to bleed out. There are many techniques and ways to perform the killing act. The main difference is between slaughtering with and without stunning, the latter being influenced by religious laws. Namely, traditional slaughterhouses forbid stunning due to religious laws (Halal or Kosher are the most well-known regulations), meaning animals are meant to die by bleeding only. In religious slaughterhouses the killing process is carried out by one or more trained professionals who use a very sharp blade to manually cut the jugular veins. Killing in traditional slaughterhouses is always a manual act bound to strict guidelines.

In abattoirs where stunning is practiced, killing can be done by hand or by using automatic equipment with backup personnel. This is mostly a matter of economics. An automatic killing machine has a single or double blade to efficiently and correctly sever the veins without damaging trachea.

After the kill cut has been made, the birds will generally lose around half of the total amount of blood in 1,5 to 2 minutes of bleeding time. The birds are conveyed over a v-shaped bleeding trough which collects the blood. Inadequate bleeding results in a product with a shorter shelf life. However letting birds bleed out too long will cause problems with plucking.

- 2000 birds per hour requires a bleeding line of approximately 10 meters

- 4000 birds per hour requires a bleeding line of approximately 20 meters

- 6000 birds per hour requires a bleeding line of approximately 30 meters

Plucking

Plucking

After the feathers have been loosened in the scalder, the birds are plucked one ore more defeathering machines. Cabinets with multiple rows or rotating discs with rubber plucking fingers are placed on both sides of the shackle line. One plucking machine can hold up to 32, 40 or 64 rotating discs with each disc containing 8 to 10 plucking fingers. The rubber picking fingers are designed to remove the feathers from the carcass.

The amount of plucking discs and machines needed, depend on the required capacity per hour. The end result is always a cleanly picked bird. Height and spacing of the discs can be adjusted to accommodate different bird sizes.

Scalding

Scalding

Before plucking and after the birds have bled out, the birds are conveyed through a water tank filled with hot, scalding water. Hence the name of the machine: scalder or scalding tank. The water can be heated by heating elements and functions to help loosen the feathers from the skin. This is absolutely vital to achieve a good defeathering result. Blowers inside the tank will create turbulence in the water, meaning the birds are completely immersed and scalded.

Three general scalding settings are:

- soft/semi-scalding at 50-52ºC for 3 minutes

- medium scalding at 54-56ºC for 2,5 minutes

- hard scalding at 58-60ºC for 2 minutes

The higher the scalding temperature, the better feathers are loosened from the follicles. However, it also has the most effect on the skin: the outer skin layer, also called epidermis, will also loosen and will be removed by the plucker. This leads to a lighter skin, which is a product preference in some countries. It is generally not recommended to combine hard scalding with air chilling, because the skin will discolor unfavorably due to dehydration in the air chilling room.

Evisceration

Evisceration is the process where the carcass is opened to remove the viscera (internal organs and intestines) from the bird. This can be done manually, semi-automated or fully automated. Manual evisceration involves knifes, scissors and other hand tools to process the birds, whereas semi-automation comes with tools powered by compressed air to reduce operator fatigue and increase worker productivity per hour. Full automatic evisceration is carried out by carousel machines which hold working units which perform the very same tasks at higher speeds per hour (stating from 3000 birds per hour up to 12000 birds per hour). Dutch Poultry Technology specialized in equipment to process 500 - 6000 birds per hour, with automatic evisceration machines which process 2000 or 6000 birds per hour.

Automatic evisceration is the pinnacle of modern poultry processing. Manual processing requires a large number of staff. However, automated eviscerating line greatly reduces needed labour. Therefore the technology allows for expanded production capacities of 4000 to 6000 birds per hour. In addition to increased productivity, there are several more advantages. Within a specific average flock weight range, a consistent product quality can be guaranteed. It also ensures safe and hygienic production according to modern food safety standards, which is a growing concern in more and more markets around the world.

Automatic Evisceration Machines

The automatic evisceration line can contain any of the machines listed below.

- Vent Cutter; cuts the vent and removes the Bursa Fabricius

- Opener; opens the vent hole to make room for the evisceration units

- Eviscerator; removes the intestines completely without causing damage

- Cropper; removes the crop and trachea by means of a drill

- Neck Breaker; breaks and removes necks

- Final Inspection machine; which removes the lungs and other organic materials by means of vacuum

- Inside/Outside Bird Washer; thoroughly spray washes the birds' carcasses from the interior and exterior

Chilling

Chilling, in this example: water chilling

Water chilling used a screw- or auger-driven chilling tank to bring down the temperature of the product to the required level. The water chiller is ideal for washing and pre-chilling eviscerated poultry prior to weighing, portioning and packing. It prevents deterioration in meat quality and microbial growth. Comes in sections of 3 and 6 meters which can be combined to match any production capacity. Water chilling is mostly suitable for frozen end product.

For fresh product, air chilling is recommended. Air chilling utilizes controlled cool air flows to bring down the temperature of the product to the required level. Only suitable for cooling fresh (meaning not frozen) product. Setup and layout depends on available space and processing requirements. Chilling by air is becoming the preferred cooling method in an increasing number of countries. The main reason is that it is a very hygienic process with a greatly reduced risk of cross contamination. And no water is used, which can be an important consideration (due to cost and availability) in some areas. One drawback of air chilling however, is that the method is only suitable for processing fresh products. If frozen chicken is the end product, water immersion is generally considered to be the preferred method of chilling.

The choice of shackle type depends on customer requirements, such as available space but also any next steps in processing. If the air chill line is retro-fitted in an existing plant where the chilling line needs to automatically transfer birds to a cut-up line, a two-leg shackle is generally recommended. Whereas a one-leg shackle type is greatly suited for automatic transfer to weighing lines. In any case, the birds hang from the shackles and are conveyed through the air chilling tunnel where they are chilled by a controlled air flow generated by coolers and fans.

(Frest) Crate Washing

Poor hygienic procedures can lead to health and safety issues. Naturally storing and handling fresh processed meat requires clean crates, free of dirt, waste and other materials which can cause food safety hazards. Any poultry processing plant requires many clean crates on a daily basis. The exact amount depends on production per hour, as well as the type of product, crate types, and so on.

In lower capacity plants cleaning can be carried out by hand, using a pressure washer and cleaning agents. There are also basic crate washer machines which automatically rinses and washes crates and only needs an operator to load and unload crates. Depending on the number of crates involved the crate washing setup can be increased to complete washing lines with wash tunnels which process hundreds or even thousands of crates per hour.

Packing / Weighing

Weighing

After the birds have been chilled, they are weighed and subsequently packed or deboned before to they are sold or further processed. In lower capacity plant it can be as simple as one or more weighing scales operated by one or more staff members. In larger plants automated weighing systems with computers are used to weigh and sort parts or whole birds.

Packing

Whole birds, portions and further processed meat are either packed in retail-ready packages or large bulk package for wholesale or industrial use. The packaging protects the product from contamination, moisture loss and any matters which might create a health or safety issue. A machine such as a bird bagger, allows an operator to bag whole birds or portions quickly and efficiently.

Blast Freezer

Blast Freezer; equipment supplied by a third party outside Dutch Poultry Technology

Freezing of the end product is done to significantly increase the shelf life, as lower temperatures will reduce the rate of deterioration. Freezing has an effect on product texture. Slower freezing rates lead to larger ice crystals which cause more damage to the meat tissue. Therefore, a faster rate of freezing is preferred which leads to the forming of relatively smaller ice crystals. A blast freezer can be used to quickly bring down the product temperature in order to complete freeze the meat. In case of fast freezing, the product temperature is brought down to approximately -20 degrees Celsius within an hour. Blast freezing is essentially blowing very cold air through the freezer room at high velocity using large fans.

While Dutch Poultry Technology doesn't provide blast freezing equipment or engineering, we will work with trusted industry partners to provide a complete solution.

Cold Store

Cold / Frozen Store

The end product is chilled by means of water or air to extend the shelf life of fresh meat. The process decreases the product core temperature from 37-39 degrees Celcius to about 5 degrees Celcius in a few hours time. In most cases, refrigerated meat is limited to a shelf life of one to two weeks. It can be economical to store the meat in cold or even frozen storage rooms to significantly increase the shelf life. A blast freezer can be used to quickly bring down the product temperature in order to complete freeze the meat. Freezing is used to store meat for extended periods, measured in weeks or months, even up to a year. Especially poultry processing companies which aim to export their meat depend on frozen storage for keeping and shipping meat.

While Dutch Poultry Technology doesn't provide cold / frozen storage equipment or engineering, we will work with trusted industry partners to provide a complete solution.

Distribution and dispatch area

When the poultry product has been processed, packed (in bags, boxes, crates or otherwise) and chilled, they are ready for pick-up by truck or lorry.

Offal Handling

Offal is a by-product in poultry processing plants. It includes feathers, blood, intestines, evisceration waste, heads and feet. Offal are the inedible parts of the bird. Even though the blood and feet (paws) are consumed in some markets, they are still considered offal. Any poultry processing plant will need to handle and transport its offal by-product. An offal pump uses water to pump the offal through a piping network to a collection area. It is possible to unload the offal materials in a water separator to separate the offal and water from the feathers. The feathers can then be processed by a feather press for dewatering. All offal materials are generally used in or sold to rendering plants. In short, rendering means converting inedible animal waste materials to meal or animal feed. For many operations it is vital to have a good offal system in place, as it can create extra value and profit.

Next to wet systems, vacuum systems can be used to transport offal waste. These efficiently transport blood/offal without the use of water. In addition to a reduction in plant water usage, it reduces labor requirements. Vacuum systems are also needed to operate some evisceration machines.

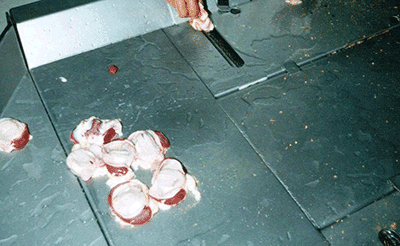

Gizzard / Intestine Handling

In the evisceration process the viscera pack (intestine, liver, gizzard, heart) are removed from the carcass. They are presented to line personnel for visual inspection. Hearts and livers can be separated and harvested for further use. Other edible parts such as the gizzard (pictured) can be processed by a gizzard harvesting setup:

The gizzard processor, with a capacity of up to 6000 gizzards per hour, separates the gizzard from the pre-stomach, cleans the gizzard en removes the skin (lining). The pre-stomach is inedible and has to be removed. Pinch off rolls separate the pre-stomach and the gizzard. To peel the inside of the gizzard, it has to be cut open by a blade. When opened, a water spray cleans the gizzard and removes any feed or digestion juices. The last step in this process is to remove the inedible inner skin, which are removed by peeler shafts which peel of the inside of the gizzard. The clean, peeled gizzards are ejected from the gizzard harvester. As a back-up check, it is possible to include a gizzard inspection table, which will allow a single operator to check and – if needed – peel any gizzards which have not been processed correctly.

The gizzard inspection table is designed to remove any gizzard lining of the gizzards. When using an automatic gizzard harvester it is recommended to use a gizzard inspection table as a quality control back-up. Any gizzards which are not or only partially processed can be peeled manually by using the peeling rolls in the table.

Engineering

The engineering department generally consists of a machine workshop, with a storage room for spare parts to enable engineers to carry out repair and maintenance work.